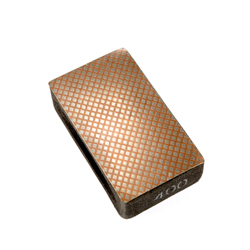

The most important tools are the basic hand chisels, a 1.5# hammer and a rasp. The first power tools should be an angle grinder (7.5 amps or more) and a diamond blade (or a Dremel if working very small) and perhaps a straight “die” grinder. The next step is a big but wonderful one: an air compressor. This will open up the world of lighter but more powerful tools.

Electric angle grinders come in different sizes which refer to the blade size they can accommodate. A 4.5″ or 5″ grinder can both use a 5″ diameter blade with the larger size having a more powerful motor. There are more rare 6″ and 7″ grinders but usually the next step up is 7/9″ “body” grinder. This is used for 7″ and 9″ blades. It is important not to put larger blades than the rating of the grinder. There are two reasons for this. A larger blade (like a 7″ on a 4.5/5″ grinder) will be too close to your fingers. Secondly, blades have safety ratings based upon speed as follows: 5″ blade – 12,000 rpm; 7″ blade – 8,000 rpm; 9″ blade – 6,000 rpm. Check the speed of the g rinder you want to purchase.

rinder you want to purchase.

Again, the higher the amperage the grinder the longer it will last through the dust we create. Get below 7.5 amps and life is usually short. The best brand of 5″ angle grinder is 11 amps. The top brands are currently Makita, Metabo and Bosch. Unfortunately, many of the known “American” brands are made in low-quality producing countries.

The other electric power tool to consider after the angle grinder is a straight or “die” grinder. These take 1/4″ shank tools particularly burrs. The air versions of these are much lighter and  cheaper but use a LOT of air – more than can be produced on a portable compressor. For under $ 150 you can get an electric version that can give you the same, albeit, heavier results.

cheaper but use a LOT of air – more than can be produced on a portable compressor. For under $ 150 you can get an electric version that can give you the same, albeit, heavier results.

Compressors open up a whole other world of tools for stone sculpting (and keeping your car tires full). A portable compressor should be rated for at least 4.6 cfm at 90 psi (30 gallons). This will run an air hammer. To drive an air grinder you need a larger stationary machine that preferably has at least 12 cfm at  90 psi (60 gallons). Tank size is noted and is an important variable. If the tank is smaller than these sizes the compressor will be running all the time which will shorten its life. If you use the portable compressor, as mentioned above, there is nothing wrong with getting an electric die grinder that uses 1/4” shaft tools.

90 psi (60 gallons). Tank size is noted and is an important variable. If the tank is smaller than these sizes the compressor will be running all the time which will shorten its life. If you use the portable compressor, as mentioned above, there is nothing wrong with getting an electric die grinder that uses 1/4” shaft tools.

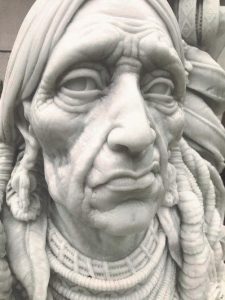

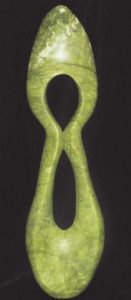

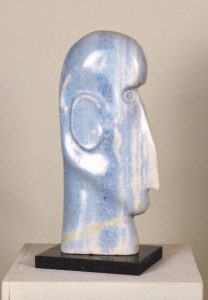

Andes Onyx by Art Wells |

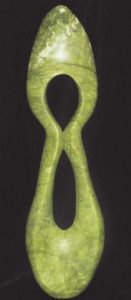

Ming Green by

Syd Summerhill |

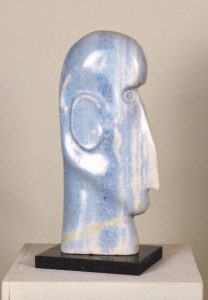

Azzurro Acquamarina by Bart Ingraham |